A great yacht starts with a design that maximizes safety and comfort, without sacrificing performance. Above the waterline or below.

A great yacht starts with a design that maximizes safety and comfort, without sacrificing performance. Above the waterline or below.

Our boats represent the perfect combination of tough, offshore capable construction supported by robust and redundant systems and married to luxurious living spaces.

A commitment to superior yacht design and construction starts with expertly engineered hulls and is carried through with our dedication to continuous innovation and improvement of every component and system on our boats. We control every aspect of the manufacturing process in our own dedicated factory with experienced craftsman and technicians who start with the best raw materials and the highest quality components.

Once launched, our yachts are supported by our unique Hampton VIP Owner's program with access to help and advice 24/7 and service arrangements worldwide.

C.Y. Chen, the founder of Hampton Yachts, loved the ocean. An avid sailor, he turned his passion for the ocean into a thriving enterprise hand-building ocean going sailboats. When the global market for sailboats declined, the Chen family applied their expertise to building ocean going motoryachts.

Since 1965, the Chen family has launched over 2,000 hulls. Hampton Yachts' flagship brands, the Endurance long range cruiser and Hampton coastal pilothouse motoryacht are acclaimed by the experts and loved by their owners. To meet increasing demand, they have set up a production plant in Taiwan.

None of their success would have been possible without their unwavering commitment to quality, design, engineering and craftsmanship. A commitment started over 50 years ago in Taiwan, by C.Y. Chen and carried-on today by his son, company Managing Director, Jeff Chen.

Hampton Yachts build their Endurance and Hampton yachts in their own dedicated factories staffed with their own craftsmen and women. Many well-known boat brands bid out their new boat orders to contract factories with the lowest price and use subcontractors to complete much, if not all, of the actual build out. In contrast, Hampton Yachts are always made in Hampton's own factory where the focus is on quality and the pride of craftsmanship shines through in every detail.

Hampton Yachts directly employs over 200 skilled craftsmen and women, many with more than 20 years of experience, including finish carpenters, designers, engineers and naval architects. Hampton Yachts is privately owned and well-funded for future growth. In addition to owning their own manufacturing plants outright, Hampton Yachts is in the enviable position in that they are debt-free.

We pride ourselves on the high level of customization available with Hampton Yachts. Because our boats are built in our own factories with our own craftsman we are able to customize any aspect of a new yacht; including layout down to the finishes. Your Hampton representative will help you choose the boat and options that meet your needs. From fireplaces to exotic wood interiors we have done it all!

And of course, you are welcome to visit our factory at any point before and during your build. Unlike many other semi-custom manufacturers, we do not require large, un-refundable deposits to secure a slot in our manufacturing schedule.

Taking care of our owners and their boats is our top priority. Enjoy safe and worry-free boating with our comprehensive training program and ongoing service support.

We will take as much time as you need to get you comfortable and confident with your new boat. Our VIP Owner's experience includes a complete run through of all your boat's systems including their operation and basic maintenance and a day of on-the-water orientation where we practice docking, picking up moorings, and maneuvering in tight spaces.

All Endurance Yachts have been designed and evaluated to meet or exceed the Weather Criterion stability standard of the US Coast Guard for licensed passenger vessels in exposed waters service (Subchapter S CFR 46 Part 170.170), proven for decades to insure passenger safety. Each and every boat is incline tested as one of the last quality checks prior to shipping to demonstrate that they exceed stability standards in light and fully loaded conditions. We build to the ABYC (American Boat and Yacht Council) safety standards for design, construction and equipage.

Our high performance hulls are designed by renowned Naval Architect Howard Apollonio and have been refined through extensive tank testing.

The new split-chine hull for the Hampton Pilothouse Motoryachts is the latest in the development of an advanced-engineered hull form. This highly refined hull is based on essential experience with many fast yachts and commercial craft for 32 years. It is also a close cousin and predecessor to the highly successful Endurance Hybrid Hull.

The Hampton Split-Chine hull was originally developed to improve the pre-planing and early-planing economy of high speed craft. Seeing that major wave-making resistance results from most other hulls’ chines that cross the waterline at a steep angle, Apollonio lowered the chine forward of midships. At typical cruising speeds, these new chines slide smoothly through the water, instead of pushing it out of the way. At higher planing speed these boats’ chines perform the same lifting function as others, so there is no disadvantage. At the same time, the low chines of these hulls smoothly penetrate waves, greatly reducing slamming and harsh ride in rough water. A well-appreciated byproduct of this feature, is that chine slap at anchor is eliminated.

In order to control a boat’s bow wave and spray, a near-level upper chine section or spray rail is built into the hull. This replaces the high forward part of conventional chines, as if the chine had been split into 2 parts. Hence the term split-chine. The height and low shallow angle of this spray rail also contributes to improved ride quality in rough water, compared to the steep forward parts of conventional chines. A constant stream of compliments has resulted from users of these hulls.

The new Hampton Split-Chine Hull has been re-shaped based on prior experience, and to particularly suit the Hampton Pilothouse yachts arrangements, weights, and centers. Plus, careful fairing of the chine and spray rail into the hull bottom further enhances its ride quality.

The Endurance Hybrid Hull was derived from this hull form by eliminating the forward part of the chine. Then, that part of the hull was re-shaped to resemble the best of high performance displacement hulls. This further reduced resistance in the pre-planing realm, typically 12-20 knots. The hybrid hull’s chines reduce squat/trim, and enable it to run well at early planing speed. At the same time, it typically matches or exceeds the economy of displacement hulls.

We choose a solid fiberglass hull for our foundation because of its inherent advantages:

Solid fiberglass is extremely difficult to puncture and forgiving in the event of a collision; carbon fiber is brittle and cored hulls can have weak spots that are impossible to visibly detect.

Solid fiberglass is the easiest material to repair in the event of a scrape or collision; carbon fiber is extremely difficult and expensive to repair and with cored hulls one must always guard against hidden defects, water intrusion and delamination.

Solid fiberglass eliminates any worry when adding additional thru hull fittings; in contrast, with cored hulls one must be very careful when adding thru hull fittings to prevent water from seeping into a cored hull where it can result in water intrusion and delamination.

The most important safety feature of any boat is a quality hull construction.

All Hampton hulls are hand-laid with Knytex or Cymax instead of conventional roving/mat construction, for greater strength and reduced weight. The 5 outer layers use Vinylester resin, to eliminate the potential for future blistering. In addition, Hampton adds 2 hand-laid layers of Kevlar reinforcement from chine to chine and a 3rd layer in the forward collision zone. This helps to create a stiff, puncture resistant structure and adds an extra layer of safety. Running gear is protected by a full length keel.

Side decks are wide and easy to navigate with extensive and well positioned on-deck rails that are oval shaped for a secure grip. Our hardware is generously sized and made of 316L stainless steel imported from Japan. Excellent sightlines from the lower helm both ahead, to the sides and aft through sliding glass doors.

We give the same consideration to visibility from the fly bridge; many boats place their flybridge helms too far aft, we carefully position our flybridge helm forward for excellent 360 degree visibility.

For confidence in tight spaces, all Hampton yachts are outfitted with additional aft control stations in the cockpit, one each on port and starboard, conveniently built into the aft deckhouse supports. We also offer an optional yacht controller for the ultimate mobile control station.

Our boats are designed to be owner operated and easy to handle and dock with proportional bow and stern thrusters, and engines that are expertly matched to each hull with generously sized twin props for power when you need it. Systems are designed for ease of use and maintenance in a true stand up engine room with interior access for safety underway.

Staircases, not ladders, to get up to the flybridge or down to the engine room. Most of our models have interior access from the salon to the engine room for safe access to the engine room while underway.

Other important safety features include collision bulkheads, escape hatches, standard fire detection and suppression systems, a custom ship's monitoring system, two anchors rigged and ready for deployment with 300' of all chain rode.

Reliability and redundancy are trademarks of our boats with in-line backups, pumps and components for all key systems including dual Racor in-line fuel filters, twin-PTO's to support the hydraulic system, two generators, back up fresh water pump, dual AC compressors, back up macerator pump, dual 75 foot cablemasters...

All wiring, mechanical systems, through hulls and pumps are well labeled and meticulously organized. Each boat comes with a unique Owner's Manual that shows the layout of the electrical, plumbing, HVAC systems in great detail, along with the serial numbers of all major components organized on a single page.

Successfully engineered reduced vibration and sound levels with tight machining tolerances and extensive sound proofing. SeaTorque anti-vibration enclosed shaft systems to further isolate the engine reducing the potential for vibration and increasing efficiency by up to 6%.

Hampton's hulls utilize a spilt-chine design. This innovative hull design is based on the latest in hydrodynamic theory and draws the best aspects of both displacement and planning hulls. Not simply a semi-displacement, or semi-planing hull, this design features an unconventional chine that reduces wave-making resistance. Our hybrid hulls increase performance without sacrificing stability and comfort.

The hull was subjected to extensive tank testing at Vizon SciTec Inc., in Vancouver, Canada in smooth and rough water conditions to ensure the hull would be efficient at higher speeds and comfortable and seaworthy in conditions up to sea state 4 (significant wave heights of 4 to 8 feet). The testing concluded the design objective of 'a comfortable cruising vessel that is seaworthy and capable of speed (when desired)' was more than met.

Underway, Hampton yachts are designed for comfort with ABT stabilizers, extensive soundproofing and isolation systems to remove vibration and noise from the cabin. At anchor, the spilt-chine reduces wave slap and the zero-speed stabilizers ensure a peaceful night's sleep.

Luxurious spaces for entertaining and living abound. Our yachts have a sophisticated open concept flow on the main deck from cockpit to salon and thru the galley to the helm.

The cockpit on the aft deck offers a venue for al fresco dining. A cleverly situated day head is easily accessible from the cockpit. A very practical luxury.

The salon is spacious and airy with glorious views from bow to stern.

The galley is meant for serious cooking with a complete complement of full sized, top-of-the-line appliances and lots of storage so you can cook and provision like you do at home.

Full-beam master stateroom is elegant and functional with king-size walk around bed, ample closets, drawers and an optional his-and-hers head arrangement or walk in closet. VIP stateroom with queen-sized bed and ensuite head. The third stateroom has twin beds that convert to a queen-sized bed when needed.

Optional crew quarters are available on most models.

Continuous improvement is the goal of every employee of Hampton Yachts. From our designers, engineers, craftsmen and everyone else involved in manufacturing our yachts, we are always looking for ways to make something better. From the major systems onboard to the small details, it is our mission to Exceed your Expectations.

The davit is positioned so your tender can be deployed off of the side or stern as conditions warrant.

Split-chine hull design eliminates annoying chine slap at anchor.

External TVs housed in cabinets that drop open for use and provide protection from elements when closed.

Bar stools have a discreet built in storage rack so they don't shift underway.

Natural light and fresh air with generous opening portholes in every cabin.

Day head in the cockpit so no one needs to enter the living spaces below to use the head.

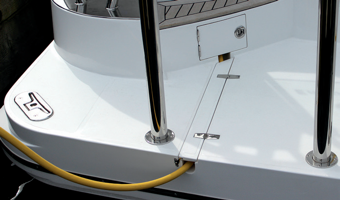

Shore power cords have their own channels under the deck so it is clear of unnecessary obstacles.

Fuel fills on both port and starboard and are tucked into their own lockers to reduce the potential for spills.

Highest quality 316 stainless steel rails. Oversized and oval shaped for security.

Customize your boat with our in-house design team who will work with you to ensure your yacht's interior reflects your needs and taste. As a semi-custom builder, Hampton Yachts offers many custom interior options, layouts and finishes on all their yachts.

New hulls come with a generous $50,000 allowance for the electronics package of the owners choosing.

Our boats are fully equipped for cruising and entertaining in safety and style but we also offer a variety of optional features including: yacht controller, water maker, tender package, security system, and more.

Join our Family of Owners!

Because we own the factory and directly employ all our engineers and craftsmen and women we control every aspect of the manufacturing process and are able to ensure each hull meets our standards for excellence. Our boats are backed by a full year warranty on all systems and a five year warranty on the hull. Each finished boat undergoes exhaustive sea trials and systems testing prior to owner delivery.

We have spent over 50 years refining our process to build the best hulls possible:

All showers and other components are seamless molded fiberglass. Hampton utilizes a common drainage system that is extremely easy to maintain, so showers will give you years of trouble-free use.

All tanks aboard a Hampton yacht are molded fiberglass, made using Vinylester resin. A food-grade resin is applied to all interior surfaces of the potable water tanks, and a fire retardant mixture is applied to all fuel tank surfaces to improve their flame resistance. All tanks are pressure tested to ensure quality.

All Hampton yachts utilize embedded frameless glazing on all fixed windows. The results in less maintenance and minimizes possible leaks. Frames can channel or trap water, thus compromising window seals resulting in leaks that can create further damage. The tempered glass venture on the fly bridge is framed in a molded FRP frame.

Natural Makore cherry wood interiors crafted from industry leading 50 Mil thick veneers from a single log with solid wood corners for an unsurpassed look of quality and consistency of grain and color. Most manufacturers use the less expensive 20-30 Mil veneers that can crack, warp and are nearly impossible to repair in the event of a scratch.

Disclaimer: Each yacht is semi-custom built; the above specifications, equipment list, and designs are subject to change.